The microstructure of an iron-carbon alloy consists of proeutectoid ferrite and pearlite; the mass fractions of these two microconstituents are 0.174 and 0.826, respectively. Determine the concentration of carbon in this alloy. engineering

Silver-Copper-Zinc-Tin Brazing Alloy | tradekorea

May 23, 2023The composition of the copper-silver alloy at 775˚C (1425˚F) is 70% copper and 30% silver, with the primary microconstituent having a mass fraction of 0.70 and the eutectic structure having a mass fraction of 0.30. The correct option is (a). To determine the composition of the copper-silver alloy, we can use the lever rule formula.

Source Image: exarc.net

Download Image

4,134 solutions Fundamentals of Materials Science and Engineering 5th Edition • ISBN: 9781119175483 David G. Rethwisch, William D. Callister 908 solutions ^2 2 -F) [57 W/ (m ^2 2 –C)], and determine the air-side surface area using (a) the LMTD method and (b) the NTU method. biology

Source Image: mdpi.com

Download Image

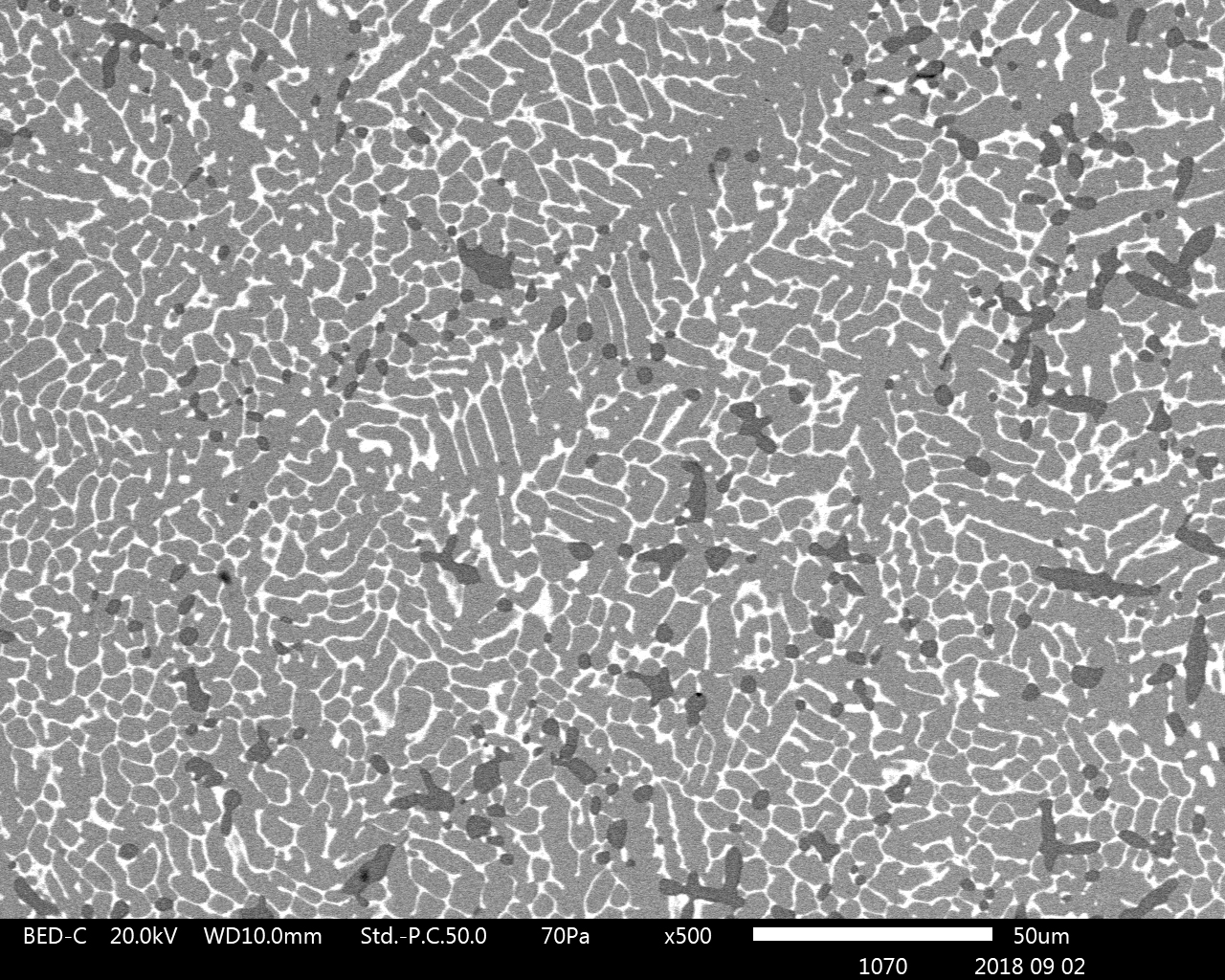

Anisotropic dynamic compression response of a directionally-cast silver– copper eutectic alloy – ScienceDirect The microstructure of a copper-silver alloy at 775^\circC consists of primary a and eutectic structures. If the mass fractions of these two microconstituents are 0.65 and 0.35, respectively, determine the composition of the alloy. the microstructure of lead tin alloy at 180 consist of primary B and eutectic structures.

Source Image: sciencedirect.com

Download Image

The Microstructure Of A Copper Silver Alloy At 775 C

The microstructure of a copper-silver alloy at 775^\circC consists of primary a and eutectic structures. If the mass fractions of these two microconstituents are 0.65 and 0.35, respectively, determine the composition of the alloy. the microstructure of lead tin alloy at 180 consist of primary B and eutectic structures. This article describes the microstructure of copper alloys, including copper-zinc (brasses), bronzes, copper-nickel, and copper-nickel-zinc, and examines the effect of oxygen content on alloy phases observed in different product forms.

Tailoring the microstructure of a Cu-0.7Cr-0.07Zr alloy submitted to ECAP at cryogenic temperature for improved thermal stability – ScienceDirect

Assume that (1) α and β phases exist at the A and B extremities of the phase diagram, respectively; (2) the eutectic composition is 47 wt% B-53 wt% A; and (3) the composition of the β phase at the eutectic temperature is 92.6 wt% B-7.4 wt% A. Determine the composition of an alloy that will yield primary α and total α mass fractions of 0.356 and Investigating the Structure, Microstructure, and Texture in Selective Laser-Melted Sterling Silver 925 | Metallurgical and Materials Transactions A

Source Image: link.springer.com

Download Image

For a 52 wt% Zn – 48 wt% Cu alloy, make schematic sketches of the microstructure that would be observed for conditions of very slow cooling at the following temperatures: a) 950C ( Assume that (1) α and β phases exist at the A and B extremities of the phase diagram, respectively; (2) the eutectic composition is 47 wt% B-53 wt% A; and (3) the composition of the β phase at the eutectic temperature is 92.6 wt% B-7.4 wt% A. Determine the composition of an alloy that will yield primary α and total α mass fractions of 0.356 and

Source Image: homework.study.com

Download Image

Silver-Copper-Zinc-Tin Brazing Alloy | tradekorea The microstructure of an iron-carbon alloy consists of proeutectoid ferrite and pearlite; the mass fractions of these two microconstituents are 0.174 and 0.826, respectively. Determine the concentration of carbon in this alloy. engineering

Source Image: tradekorea.com

Download Image

Anisotropic dynamic compression response of a directionally-cast silver– copper eutectic alloy – ScienceDirect 4,134 solutions Fundamentals of Materials Science and Engineering 5th Edition • ISBN: 9781119175483 David G. Rethwisch, William D. Callister 908 solutions ^2 2 -F) [57 W/ (m ^2 2 –C)], and determine the air-side surface area using (a) the LMTD method and (b) the NTU method. biology

Source Image: sciencedirect.com

Download Image

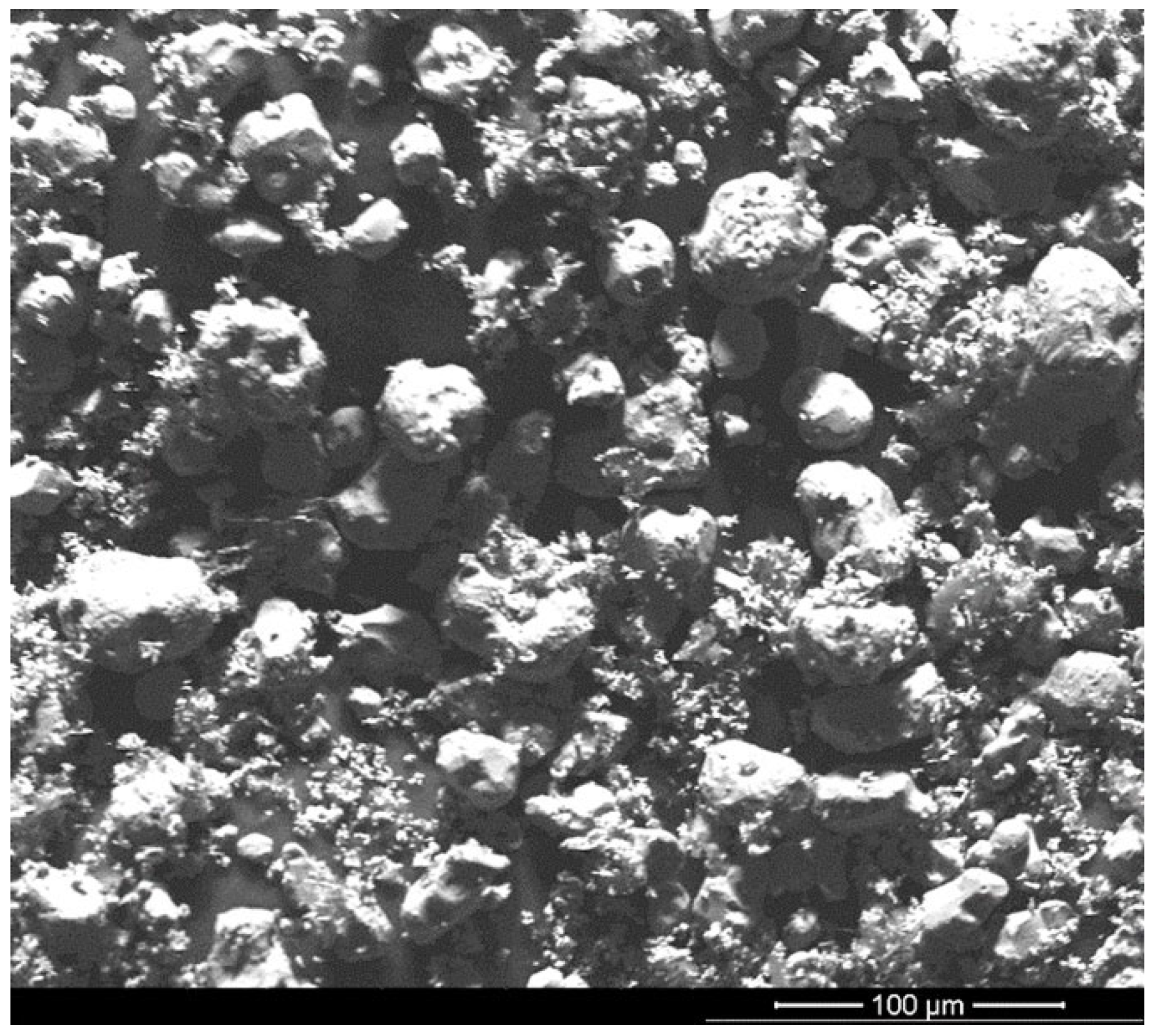

Silver Foams with Hierarchical Porous Structures: From Manufacturing to Antibacterial Activity | ACS Applied Materials & Interfaces the microstructure of lead tin alloy at 180 consist of primary B and eutectic structures. If the mass fractions of these two microconstituents are 0.57 and 0.43 determine the composition of the alloy; The microstructure of a copper-silver alloy at 775 ^oC (1425 ^oF) consists of primary and eutectic structures.

Source Image: pubs.acs.org

Download Image

Microstructures of ancient and modern cast silver–copper alloys – ScienceDirect The microstructure of a copper-silver alloy at 775^\circC consists of primary a and eutectic structures. If the mass fractions of these two microconstituents are 0.65 and 0.35, respectively, determine the composition of the alloy. the microstructure of lead tin alloy at 180 consist of primary B and eutectic structures.

Source Image: sciencedirect.com

Download Image

Solved The microstructure of a copper-silver alloy at 775°C | Chegg.com This article describes the microstructure of copper alloys, including copper-zinc (brasses), bronzes, copper-nickel, and copper-nickel-zinc, and examines the effect of oxygen content on alloy phases observed in different product forms.

Source Image: chegg.com

Download Image

For a 52 wt% Zn – 48 wt% Cu alloy, make schematic sketches of the microstructure that would be observed for conditions of very slow cooling at the following temperatures: a) 950C (

Solved The microstructure of a copper-silver alloy at 775°C | Chegg.com May 23, 2023The composition of the copper-silver alloy at 775˚C (1425˚F) is 70% copper and 30% silver, with the primary microconstituent having a mass fraction of 0.70 and the eutectic structure having a mass fraction of 0.30. The correct option is (a). To determine the composition of the copper-silver alloy, we can use the lever rule formula.

Anisotropic dynamic compression response of a directionally-cast silver– copper eutectic alloy – ScienceDirect Microstructures of ancient and modern cast silver–copper alloys – ScienceDirect the microstructure of lead tin alloy at 180 consist of primary B and eutectic structures. If the mass fractions of these two microconstituents are 0.57 and 0.43 determine the composition of the alloy; The microstructure of a copper-silver alloy at 775 ^oC (1425 ^oF) consists of primary and eutectic structures.